Your benefits:

- No warm up time required

- Quick response

- High measurement accuracy

- Measurement of oxygen level during welding process

- Measurement of mixed gases with no change in settings

- Water resistant sensor

- Multi range power supply

- Purge results data logging

Technical:

When using the orbital welding process, the most effective way to ensure a consistent and clean internal weld profile is use a back purge with a very low oxygen concentration. The only way to ensure that this oxygen concentration is low enough is to use an accurate measuring instrument. In the past manual welders often used formulas with time, flow rate and volume which give very rough indications and which are not precise enough for many applications. Even simple and low priced measuring units are no longer matching the requirements in Pharmaceutical, Biotechnology and Semiconductor Industry.

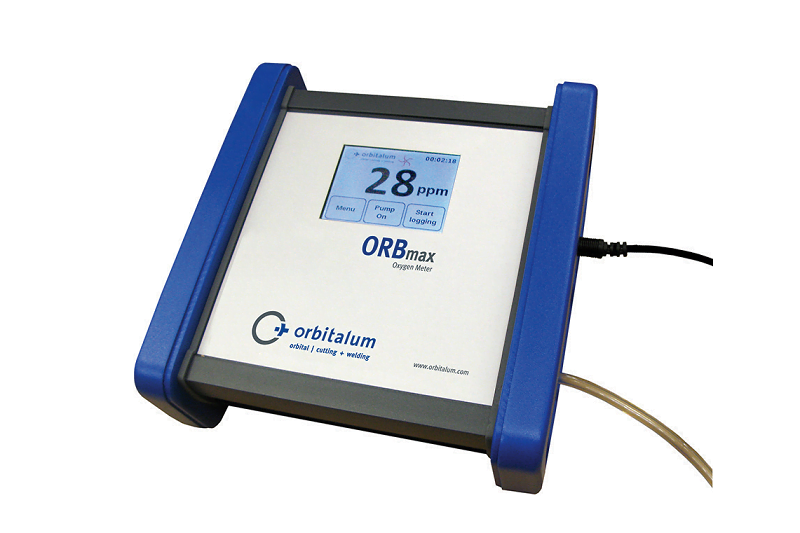

With the Orbmax Monitor you have a system which works with high precision but nevertheless is very easy in operation and economically priced. A perfect addition to an Orbital Welding System