Features

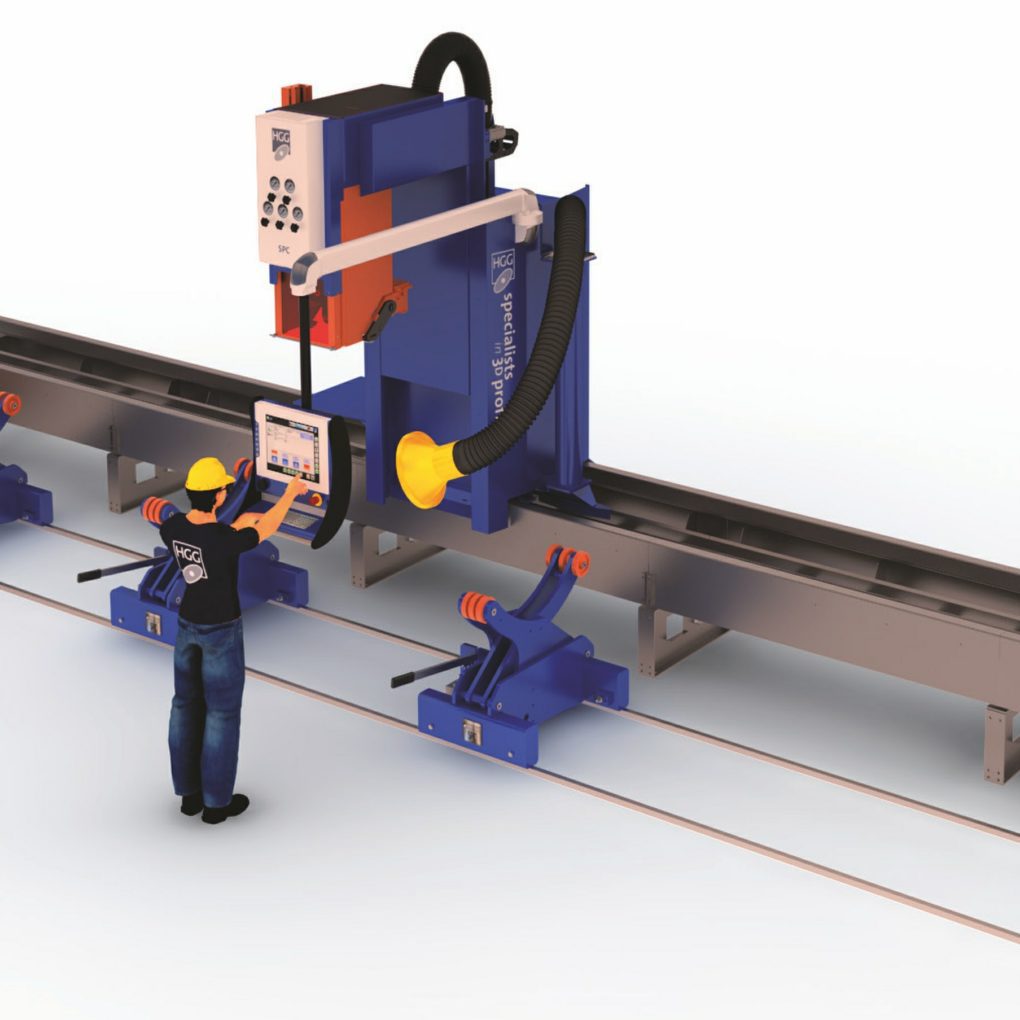

Press and Play Machine Operation – Intuitive and user friendly machine interface

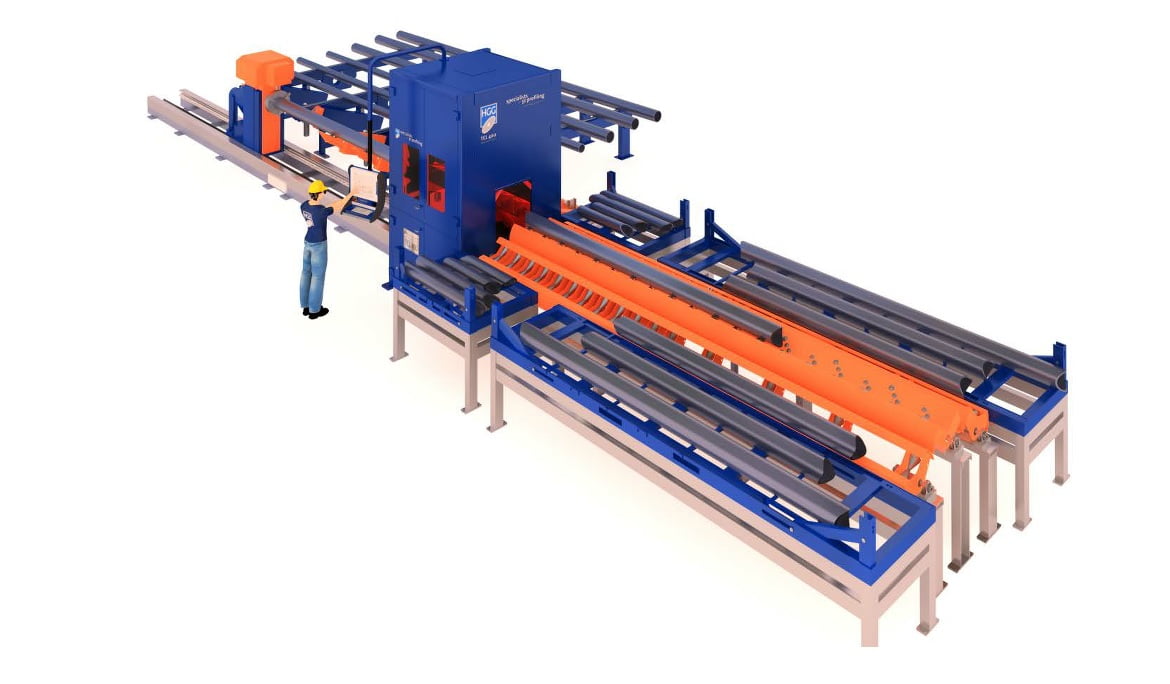

Automated Pipe Loading – The large pipe buffer allows the loading of multiple pipes (bundle) at once. The infeed of pipes into the cutting cell occurs fully automatically

Accurate pipe cutting – The use of a chuck prevents slip and creep during cutting. A high precision biaxial AutoFocus robot is used inside the cutting cell.

Effective fume extraction – Achieved by using a cutting cell. Fumes generated inside the pipe are extracted up the pipe through the main drive.

Sideways aligned outfeed – The sideways aligned outfeed configuration sorts parts on sloped tables adjacent to the outfeed gutter, this is so that they roll to the far end.

Working Range:

Pipe OD 48-406mm

Work piece Weight 4.2T

Work piece Length Max 6-12M